News: All News

Shiv Nadar Institution of Eminence signs MOU with Canon India Private Limited

On February 5, 2026, CANON INDIA PRIVATE LIMITED and the Shiv Nadar Institution of Eminence formalized their collaboration through a Memorandum of...

Memorandum of Understanding with Queen Mary University of London

Memorandum of Understanding with Queen’s Mary University of London Shiv Nadar University has recently signed an agreement with Queen Mary...

2026 International Collaborative Research Grant Winners

P.C. Saidalvi Shiv Nadar University, Nidhin Donald, Humboldt University of Berlin and Joel Lee, Williams College have won this...

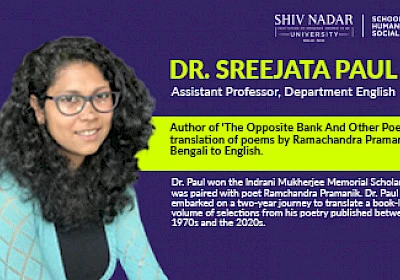

The Opposite Bank and Other Poems – a translation of poems by Ramachandra Pramanik from Bengali to English

Dr. Sreejata Paul, PhD , Assistant Professor, Department of English, Shiv Nadar University , has authored the book The Opposite Bank and Other...

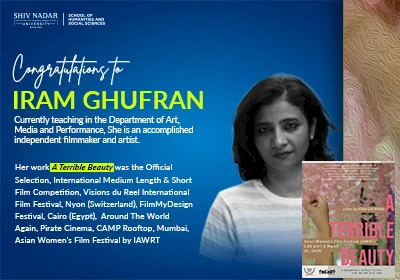

Iram Ghufran: Exploring Social Worlds Through Film and Art

Iram Ghufran is an accomplished independent filmmaker and artist, currently teaching in the Department of Art, Media, and Performance at the ...

Ig Nobel Prize for Engineering Design

Dr. Vikash Kumar , Assistant Professor of Design at Shiv Nadar University , and student researcher Sarthak Mittal have been awarded the Ig Nobel...

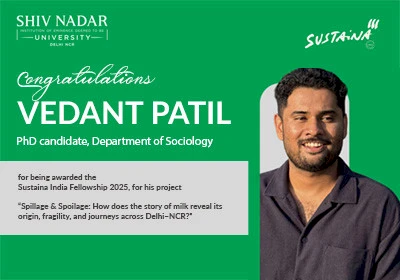

Vedant Patil awarded the Sustaina India Fellowship

Vedant Patil , a third-year Ph.D. candidate from the Department of Sociology, has been awarded the Sustaina india Fellowship 2025. The Sustaina...

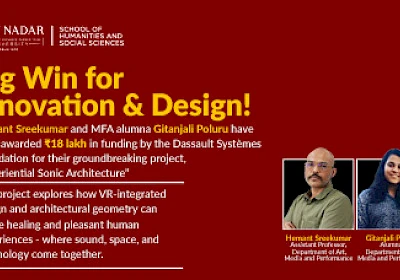

Funding from DASSAULT SYSTEMES FOUNDATION

Hemant Sreekumar, in the Department of Art, Media, and Performance, and our alumnus Gitanjali Poluru , who serves as his Research Assistant, have...

Professor Raina appointed UNESCO Co-chair

Professor Rajeswari Raina has been awarded the co-chairship of the Bernard Maris UNESCO Chair, hosted by Sciences Po Toulouse, France, under the...

Professor Himanshu Kulkarni Becomes First Recipient from the Indian Subcontinent of the International Water Prize

Professor Himanshu Kulkarni, Professor of Practice in Rural Management at Shiv Nadar University, has become the first recipient from the Indian...

Satyam Kalon: Shiv Nadar University’s New Global Partnership in Arts with Trinity Laban

Exciting Announcement: A New #GlobalPartnership in the Spectrum of Arts Shiv Nadar University, Delhi-NCR has entered into a landmark collaboration...

Dr. Vikram Kapur Honoured with International Literary Prizes

Dr. Vikram Kapur has jointly won The Letter Review Prize for Books for an excerpt from his novel-in-progress, Gandhi Colony. This prestigious...

Dr Ghanshyam Pal appointed Senior Member of INAE

Dr Ghanshyam Pal has been elected a Senior Member of the Indian National Academy of Engineering (INAE), marking a significant recognition of his...

Clever Soap For A Cleaner Future

The ubiquitous soap occupies the least space in any household, and a large part of human perception about hygiene and notions of beauty. According...

Nanocrystals in the Spotlight: Orchestrating a ‘Light’ Revolution

In the rapidly evolving world of optoelectronics, where light and matter interact on timescales of trillionths of a second, Dr. Tushar Debnath and...

'India cannot grow by ignoring half its talent'

India’s economic and social ambitions will remain a distant dream unless women are given equal opportunity, investment and safety, Kanta Singh,...

Folding Under Pressure: How Living Cells Maintain Their Delicate Balance

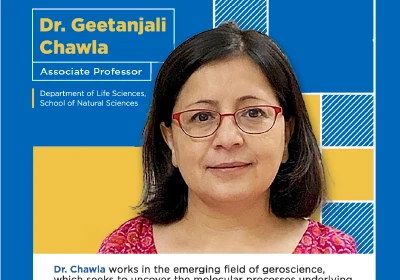

Inside every living cell is a high-stakes balancing act that ensures proteins are made, folded, and discarded with precision. But what happens when...

Professor Subhabrata Sen Wins 2025 Royal Society of Chemistry Horizon Prize

In a groundbreaking moment for Indian science, Professor Subhabrata Sen and his team from the School of Natural Sciences at Shiv Nadar University,...

Dr. V. Narayanan: Son of the Soil with Sights on Stars

It's not always that one gets to break bread with the chief of the Indian Space Research Organisation (ISRO). Dr. V. Narayanan is a man on a...

University celebrates 11th Convocation with many firsts

Shiv Nadar University celebrated excellence, diversity, hard work and gratitude on Saturday during the Eleventh Convocation. The state-of-the-art...

The School of Natural Sciences Welcomes New Visiting Faculty to the Department of Chemistry

Srijita Banerjee The School of Natural Sciences at Shiv Nadar University is proud to welcome four distinguished scientists as newly appointed...

The Molecular Science of Ageing: How Nutritional Interventions Can Improve Health

Ageing is inevitable, but does illness have to be? In 2024, the National Council on Aging in the US reported that nearly 95% of adults over the...

Influencing Incipient Researchers: How Community and Institutional Events are Shaping the Life Sciences in India

YIM 2025: Preparing the Pioneers of Tomorrow Organised by India Bioscience and co-supported by Shiv Nadar Institution of Eminence (SNIoE) and...

AI in Academia: Transforming Higher Education

The Information Technology Office at Shiv Nadar University, Delhi NCR, organized a day-long workshop - 'AI in Academia: Transforming Higher...

Sociology PhD Scholar Manish Kumar receives IPN's Small Grant

First-year PhD candidate Manish at the Department of Sociology has received the Indian Pastoral Network Small Grant for his research project titled...

World in Flux: Geopolitics in the Age of Disruption

The timeless aphorism of Italian philosopher Antonio Gramsci - The old world order is dying, and the new world struggles to be born. Now is the...

Hydrologist Dr. Himanshu Kulkarni receives the 2025 International Water Prize

Dr. Himanshu Kulkarni, Professor of Practice from the School of Humanities and Social Sciences at Shiv Nadar University, has been named the 2025...

Shiv Nadar IoE join hands with Foxconn India

Shiv Nadar Institution of Eminence Deemed to be University has inked a Memorandum of Understanding (MoU) with Foxconn Hon Hai Technology India Mega...

Shiv Nadar University shortlisted for THE Asia Awards 2025

The University has been shortlisted in the ‘Outstanding Contribution to Regional Development’ category for the SHIKSHA Plus – Adult Literacy...

Shiv Nadar University is now ranked in all the major rankings

Shiv Nadar University is now ranked in all the major rankings Shiv Nadar University is now ranked by the major ranking, national and international,...