Thermal Barrier Coatings

The project aims to design and develop optimum high entropy oxide-based ceramics exhibiting low thermal conductivity and mechanical stability at high temperatures so that they can be used as thermal barrier coating to protect components of high temperature applications such as aerospace, nuclear energy etc.

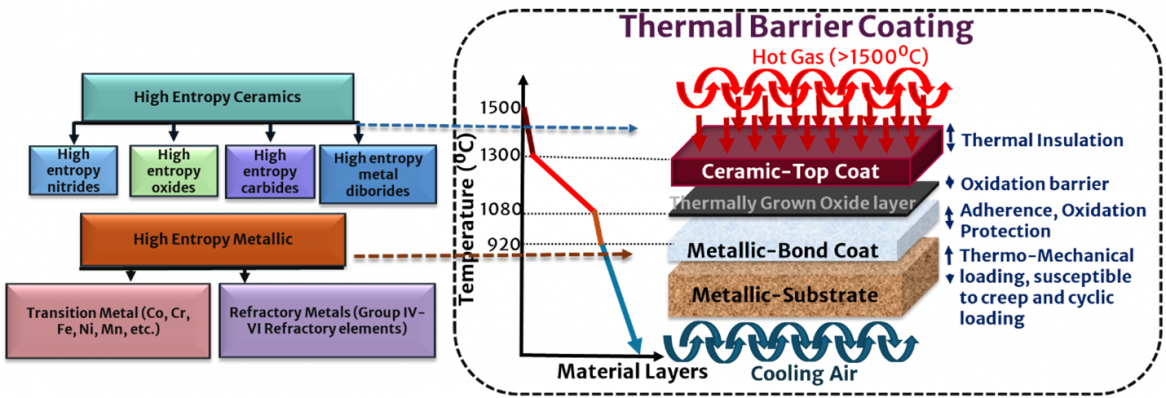

Applications such as gas/steam turbine engines, industrial furnaces, nuclear reactors, rocket nozzles, supercritical boilers, spaceship re-entry shields, hypersonic nose cones etc. involve several components which operate in high stress, intense vibration and extremely high temperatures. These components must be fabricated from specialized materials that ensure excellent structural integrity despite operating in extremely harsh environments and high temperatures, extending service life and enhancing safety. The material of construction of the components must exhibit high thermal and mechanical stability, and resistance to oxidation, corrosion and creep. To this end, a promising approach would be applying Thermal Barrier Coating (TBC) onto the metal alloy substrate base material.

High Entropy Materials (HEM) are a pioneering class of advanced materials are one of the 4th generation industrial materials.This project aims to develop High Entropy Ceramic (HEC) materials having low thermal conductivity and high thermal and mechanical stability as thermal barrier coatings (TBC) for Ni based superalloys to improve the overall durability of the substrate from high temperature, erosion and corrosion. This will be done through a systematic multiscale modeling approach by a combination of molecular simulations, structure-property relations, and multiscale simulations followed by synthesis and characterization.

For the systematic development of HEC, the first objective will be to identify and rationally select the constituents and concentration of oxide based HEC materials based on the thermal and mechanical properties derived from molecular simulations (using BIOVIA Material Studio and pipeline pilot software). The second objective will be multiscale simulations to study the strength of HEC coating on the substrate (using ABAQUS software). The HEC material as per the composition identified using molecular and continuum simulations will be synthesized in the laboratory and characterized for microstructural, mechanical and thermal properties.

The structure-property relationships of various HEC compositions which will be developed in the present study could act as critical inputs in the field of developing new HEC based TBC materials. At the end, all this exercise would certainly benefit the general public as the carbon foot print from the power plants will be reduced and power generation capacity and efficiency of power plants will be increased. Other industrial beneficiaries would be the companies developing pipeline materials transporting hot and corrosive fluids, turbine blades for power plants, nuclear power industry. The findings from this project may also be beneficial for Government of India agencies such as DRDO and HAL for improving defense and aviation systems.

Funding agency: La Fondation Dassault Systèmes

Team: Dr. Yamini Sudha Sistla (Principal Investigator)