Biodegradable Packaging Films

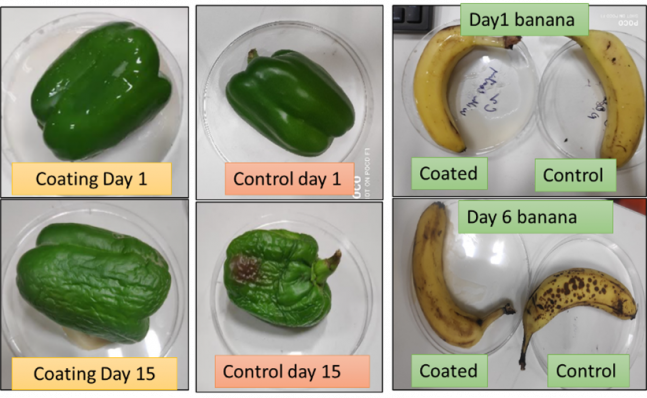

This project aims to develop edible coatings and biodegradable packaging films to improve the shelf life of fresh produce and processed foods. The ultimate aim is to reduce the use of single use plastic in food packaging and mitigate microplastics related concerns to environment and human and animal health.

With growing urbanization and improved living standards, demand for high-quality, extended shelf life, and ready-to-eat foods has also increased. This led to significant growth in the food packaging and storage industry. Due to lack of proper disposal/ recycling methods, the conventional petroleum derived synthetic plastic packaging material based on polyethylene, polypropylene, polystyrene, polyethylene terephthalate, etc., proved harmful to the environment, human, animal, and aquatic life in many ways. Therefore, biopolymer based biodegradable and edible food packaging offer a sustainable solution. A good packaging film should be transparent, should provide excellent moisture barrier properties and controlled equilibrium levels of oxygen/carbon dioxide, flexible and strong, thermally and mechanically stable at processing, storage and transportation conditions, homogeneous and free of micro cracks. From scale-up point, the films should be produced at low cost. The biopolymer to be chosen for developing films or coatings depends on the type of food being packed. Further, each biopolymer suitable for developing films does not provide all the required properties. Therefore various functional additives such as hydrophobic agents, plasticizers, binders, fillers, antimicrobial and antioxidant agents, emulsifiers are incorporated into the biopolymer matrix to improve the overall properties of the film. The properties of the film significantly depends on the evolution of film microstructure during solvent evaporation (drying) step. The microstructure of the film depends on factors such as pH, concentration and rheological properties of film forming solution, properties and concentration of components, drying conditions such as temperature and humidity and the capillary/residual stresses during drying and subsequent deformation and coalescence/curing. Studying the film formation process at microscopic level is critical because, the failure or poor-efficiency of films when developed in large scale could be due to several factors such as (i) poor rheological, physical and chemical properties of film forming solution (iii) weak emulsion uniformity and stability (iv) non-uniform distribution of stresses during drying (v) non-uniform thickness of films.

Therefore, this project aims to study all the aspects mentioned above to provide solutions for scaling up the production of high-performance biopolymer based films for example as film sheet rolls without breaks or cracks.

Funding agency: SERB-SURE

Team: Dr. Yamini Sudha Sistla (Principal Investigator)