What If You Could Simulate a Whole Plant First? Start with Modeling in B.Tech. Chemical Engineering

Blog / July 27, 2025

B. Tech. Chem. Engg.B. Tech. Chemical Engeering AdvantagesB.Tech. Chem. Engg. with SimulationSimulation is the new safety net!

The global simulation market was valued at US$72.44 billion in the year 2024, and is projected to grow to US$172.33 billion by 2032. The reason behind this massive growth is due to its rapid advancements, driven by AI, digital twins, and cloud technologies. Many leading industries are adopting simulation for innovation and efficiency.

As we know, even a minor design flaw or error in the plant’s heat exchanger, or a miscalculated pressure drop in the distillation column, can lead to a million-dollar shutdown and dangerous situations in chemical engineering. That’s the major reason why industries are relying on modeling and simulation to perform tests, tweaks, and perfect processes long before they are designed.

This shift is not just happening in industry. But it’s become a core part of how future engineers are trained. This transformation highlights why chemical engineering programs need to integrate simulation into their curriculum as a core part from the first semester. It helps students pursuing a B.Tech. in Chemical Engineering become immersed in the tools and techniques that enable them to model complex systems and simulate real-world scenarios.

Simulation has now become the modern engineer’s must-have tool! Explore how this transformation is defining the next generation of chemical engineers.

Why Traditional Methods are no Longer Enough?

When we talk about decades ago, chemical engineering relied on manual calculations, theoretical problem-solving, and experiments. Those fundamentals still matter, but you can’t keep up with the pace and complexity of modern industry demands.

Today, plants handle enormous volumes, intricate reactions, and tight efficiency goals. Designing and optimizing these plants using pen-and-paper methods is no longer practical.

Let’s better understand by taking an example, a refinery that aims to reduce its energy consumption by 15%. This is where engineers keep guessing which parameter would work without simulation. But, they can test a number of possibilities in a matter of hours with a simulation.

What is Process Simulation and Modeling?

In chemical engineering, simulation involves the process of creating a mathematical and computational representation of a physical system. On the other hand, simulation means running the model under various conditions to see how it behaves. Engineers can test “What If” scenarios without touching a real plant with these tools.

Simulation allows engineers to turn their ideas into actionable designs.

Why It’s Now Core to the B.Tech. Curriculum?

B.Tech. in Chemical Engineering Modeling and Simulation syllabus is not what it used to be. Universities are now aware of the evolving requirements of industries, and that’s why they are changing the curriculum to meet the demands.

So, what has changed?

- Universities emphasize simulation software as a basic skill because recruiters now demand proficiency

- Labs are no longer focused on hands-on glassware; they also include virtual labs and

- Programs involve project-based learning, where students get a chance to simulate entire plants as their capstone projects

The importance of modeling and simulation in chemical engineering is also recognized by the accreditation bodies like AICTE and ABET.

Benefits of Integrating Simulations into the Curriculum

Here’s what modeling and simulation bring to the table:

Safer and More Affordable Learning - You have a chance to test failure conditions or extreme cases without risk or cost.

Faster Prototyping - Try numerous designs before selecting the best one.

Deeper Understanding - You can see theory in action, like mass transfer, becomes real when you watch how diffusion plays out in a simulation.

Capstone Projects - In the final year, you will simulate the entire process flow of an industrial plant.

These will prepare you for real-world challenges.

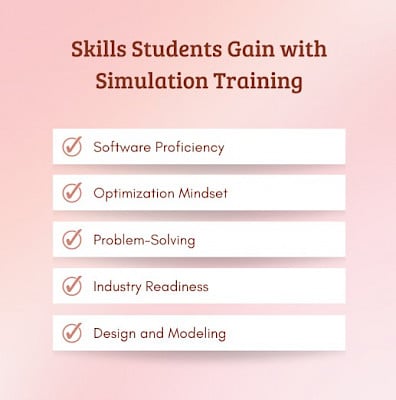

Skills Students Gain with Simulation Training

B.Tech. in Chemical Engineering Modeling and Simulation syllabus equips students with a range of valuable skills. Here are some core skills that students will gain:

- Software Proficiency - Learn multiple software programs such as Aspen, MATLAB, or Python-based modeling

- Optimization Mindset - Tweak, iterate, and test processes for maximum output

- Problem Solving - Diagnose system failures before they happen

- Industry Readiness - Confidently step into R&D, design, operations, or consultancy roles

- Design and Modeling - Gain experience in creating virtual models of chemical plants, equipment, and processes

Your Future in Process Innovation Begins Here: B.Tech. Chemical Engineering @ Shiv Nadar University (Institution of Eminence)

Choosing Shiv Nadar University to pursue a B.Tech. program in Chemical Engineering with a modeling and simulation specialization is the best decision. The School of Engineering has future-facing B.Tech. programs that prepare learners academically. The university supports students in developing a solid understanding of the fundamental principles, provides an opportunity to take on meaningful research, and offers an industry-driven curriculum. The degree focuses on hands-on learning, advanced facilities, and specialized faculty to prepare students to responsibly handle real problems and navigate future career paths.

Apart from this, many factors make Shiv Nadar University the best choice for chemical engineering:

- Opportunity for Undergraduate Research (OUR) program for research projects

- Specialized curriculum design for evolving demands of industries

- Advanced laboratories equipped to meet global standards

- Industry collaboration, internship opportunities, and placement support

- Faculty includes PhDs and researchers from leading institutions with experience

For students seeking a dynamic and impactful career in chemical engineering, Shiv Nadar University provides a compelling blend of strong academics, practical learning experiences, and industry connections.

Closing Remarks - Simulate Today to Engineer Tomorrow

The future of engineering does not rely solely on beakers and blueprints - it relies on bits and bytes. In today’s world, plants are becoming smarter, cleaner, and more complex, where simulation plays an essential role. It provides the clarity and control to optimize them.

If you are someone who aims to pursue a B.Tech. in Chemical Engineering, make sure you select a program that integrates modeling and simulation as a fundamental skill. This is where you can choose Shiv Nadar University as it offers a future-focused curriculum that helps you simulate the process and optimise the plant effectively. Apply now!

FAQs

What is the meaning of modeling and simulation in chemical engineering?

In chemical engineering, simulation means developing a mathematical and computational representation of a system, whereas simulation involves running the model under numerous conditions to optimize its behavior.

What changes are made to the B.Tech. in Chemical Engineering syllabus?

B.Tech. in Chemical Engineering modeling and simulation syllabus includes essential changes such as simulation software as a basic skill, virtual labs, and project-based learning.

What skills do students gain with simulation training?

Students will acquire numerous skills like software proficiency, optimization mindset, problem solving, industry readiness, and design and modeling.