From Thermodynamics to Process Design - Why Chemical and Mechanical Engineers Think Differently (But Often Work Together)

Blog / July 25, 2025

Chem. Vs Mech. EngineeringB.Tech. Chem. EngineeringB.Tech. Mech. EngineeringIf you have studied science in class 12, you must have seen these two formulas:

dU=dQ+dW

dU=dQ−dW

For those who have never come across this, they will think that one of the above two formulas is definitely wrong. But what if both are actually correct, and essentially represent the same principle?

Confusing? Well, this is the magic of science.

Both of the above-mentioned formulas represent the First Law of Thermodynamics. The first formula with the positive sign is correct as per the sign conventions of physics, frequently used in Mechanical Engineering, where work done on the system is considered positive. While at the same time, the second formula is correct as per the sign conventions of chemistry, which is frequently used in Chemical Engineering, where work done by the system is taken as positive, and hence, work done on the system is negative.

This example clearly shows that both of these engineering branches think differently but often work together.

Let’s go through the comparison of chemical engineering vs mechanical engineering in detail, and explore how they both shape the direction of different industries, sometimes working in complete isolation with each other, sometimes working in a synchronous way.

Shared Laws, Split Intent: How Thermodynamics Solves Different Problems in Mechanical and Chemical Engineering

Both chemical and mechanical engineers study the laws of thermodynamics. These laws deal with heat, energy, and how matter behaves under different conditions.

Thermodynamics is one of the key pillars of both chemical and mechanical engineering. Students from both the branches study the laws of thermodynamics which deals with heat, energy, and how matter behaves under different conditions.

But, how these laws are used in chemical engineering vs mechanical engineering is quite different.

|

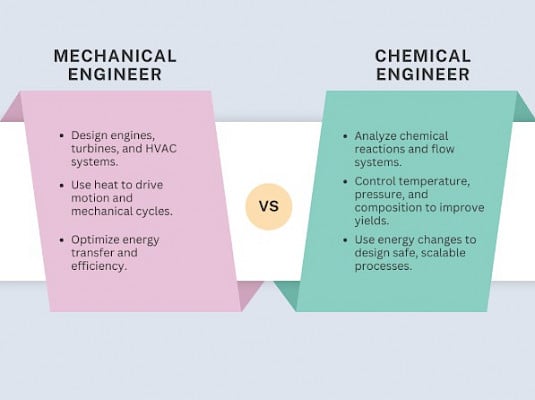

A mechanical engineer applies Thermodynamics to:

|

A chemical engineer applies Thermodynamics to:

|

For example, let’s take the Rankine cycle.

A mechanical engineer uses it to design steam turbines. At the same time, a chemical engineer uses it to decide how to recover energy in a petrochemical plant.

This is such a great example of the same concept used for different purposes.

This is why B.Tech. Mechanical Engineering focuses more on machines and their thermal behavior, while B.Tech. Chemical Engineering leans into phase changes, equilibrium, and reaction thermodynamics.

System vs Substance: How Each Discipline Frames ‘What Needs to Be Engineered’

Now, let’s go a step forward in the comparison of chemical engineering vs mechanical engineering and find out what the key focus of each is.

The mechanical engineering branch is centered around:

- Shape

- Motion

- Forces and

- Systems that move, support, or rotate

Chemical engineering focuses on:

- Flow

- Transformation

- Mass and heat balance and

- Substances reacting, separating, or purifying

So when one asks “chemical engineering vs mechanical engineering”, this context becomes crucial. One discipline builds the system; the other engineers the substance inside it.

|

Discipline |

Focus Area |

Typical Outputs |

|

Mechanical Engineering |

Form, force, thermal stability |

Engines, pumps, machines, robotics |

|

Chemical Engineering |

Composition, flow, chemical transformation |

Reactors, separation units, chemical plants |

Design Thinking vs Process Thinking: What Each Engineer Optimizes For

How one thinks shapes, how one solves problems. This is where the paths really diverge.

The set of problems one will address is directly related to the kind of thinking they have. This is where the paths of B.Tech. Mechanical Engineering and B.Tech. Chemical Engineering separate from each other.

|

Mechanical Engineering |

Chemical Engineering |

||

|

Design Thinking |

Examples |

Process Thinking |

Examples |

|

|

|

|

In short, mechanical engineering is about design thinking and involves how something should look and move. But chemical engineering is about process thinking and involves understanding how something should change and flow.

Here’s how this difference plays out in the real world:

|

Job Domain |

Mechanical Engineer Task |

Chemical Engineer Task |

|

Power Plant |

Design steam turbines |

Monitor boiler efficiency and emissions |

|

Pharma Factory |

Build tablet packaging machines |

Control drug synthesis and purity levels |

|

Oil Refinery |

Ensure integrity of pressure vessels |

Optimize fuel distillation and cracking |

Both are problem-solvers. But while mechanical engineers model how things stand, spin, or slide, chemical engineers model how things react, flow, and separate.

Mechanical Robustness vs Process Efficiency: What Real-World Engineering Plants Actually Need from Both

This is where the debate around chemical engineering vs mechanical engineering moves from theory to real-world problems.

In any industrial plant:

- Chemical engineers focus on how well the process runs: conversion rates, yields, reaction control.

- Mechanical engineers ensure the plant holds up: pressure, stress, thermal stability, wear & tear.

Let’s take the example of an ammonia plant:

- A chemical engineer’s task is to design and control the Haber-Bosch reaction, ensure the right mix of nitrogen and hydrogen, and control the temperature and pressure.

- A mechanical engineer’s role in this plant is to make sure the reactor shell survives under extreme atmospheres, handles heat cycling, and does not crack for any reason.

If anyone from them misses their mark, the plant fails. This balance is required across industries:

|

Plant Type |

Mechanical Focus |

Chemical Focus |

|

Fertilizer Unit |

Pressure vessels, rotating machinery |

Yield, purity, reaction stability |

|

Food Processing |

Heat exchangers, conveyors |

Sterility, batch consistency |

|

Petrochemical Plant |

Pumps, compressors, pipelines |

Fractionation, thermal cracking control |

The synchronization of chemical and mechanical engineering is necessary, not optional. Because a perfect process design with a weak mechanical setup is unsafe, and a robust machine without process control is inefficient.

Why Top Projects Demand Integrated Engineering Thinking

Most of the industries nowadays are not separating different engineers, but they are building a cohesive team by including mechanical, chemical, and other engineers so that the output efficiency doesn’t get hampered for any reason.

When all kinds of engineers handling different responsibilities in a project work on the same page, the probability of anything going wrong reduces to a great extent.

Take pharmaceutical manufacturing, for example. The drug synthesis route comes from chemical engineers. But the continuous manufacturing setup, dryers, mixers, conveyors, etc, is a domain controlled by mechanical engineers. Any form of miscommunication or lack of clarity can cause a reduction in production efficiency or even the failure of one or more components of the plant.

This hybrid collaboration is becoming standard across industries, including:

- Green hydrogen projects

- Battery recycling units and

- Carbon capture systems

This evolution has shaped curriculum changes, too. Chemical and mechanical engineering students work together in simulation-led labs on projects involving:

- CFD (computational fluid dynamics)

- Process equipment design and

- Thermal simulations

In the new-age industry, it is impossible for different engineers to work independently from each other. To run everything in a smooth way, projects demand an integrated effort.

Not Chemical Engineering Vs Mechanical Engineering, but, Chemical Engineering and Mechanical Engineering

Gone are the days when industries used to hire professionals who have expertise in one specific domain, but have absolutely no idea about the domain with which they will work very closely in the industry. Now, hiring managers look for people who have proficiency in their core domain of work, but also understand the nuances of other domains that are closely related to them.

Here’s where hybrid fluency comes in, knowing the core of one’s discipline, but also being aware of the basics of the other. Some trends pushing this shift:

- Process automation: PLCs, SCADA, and DCS systems now control flow, pressure, and even thermal behavior.

- Simulation-first design: Before building, plants are simulated, requiring thermal, chemical, and structural inputs.

- Sustainability: Reuse of heat, recovery of emissions, and zero-waste design require combined efforts.

From a career point of view, this opens up roles in:

- Process safety and risk engineering

- Equipment design in oil & gas or pharma

- Energy optimization in manufacturing plants and

- Simulation and control system design

A student who understands both the structural heart and the process brain of a system is much more valuable.

Build What the Future Demands: Start Your Engineering Journey at Shiv Nadar University (Institution of Eminence)

An ordinary university will teach you how to solve equations and get answers, but the right one will teach you not just to solve existing problems but also to predict, determine impact, and be prepared for upcoming challenges.

At Shiv Nadar University, engineering courses are not just about covering a pre-determined syllabus. They are about building cognitive intelligence to think across disciplines, build with purpose, and shape what’s next.

The School of Engineering at Shiv Nadar University brings together cutting-edge labs, global faculty, and a culture of research that starts from day one. Every engineering program, whether it is B.Tech. Mechanical Engineering or B.Tech. Chemical Engineering or any other stream, is designed with the requirements of the modern world. Here, students are encouraged to take crossdisciplinary electives, participate in live projects, and explore research through the OUR (Opportunity for Undergraduate Research) initiative. The freedom to select a major and minor specialization gives students a chance to be an expert in what they like the most and enjoy working with the most.

Conclusion

Deciding between chemical engineering vs mechanical engineering is not just a course decision; it’s a reflection of how one thinks and solves problems.

Whilst chemical engineering emphasizes flow, reactions, and material transformation, mechanical engineering is centered around machines, motion, and structural integrity. Both streams rely on shared scientific laws, but these can be implemented in distinct ways.

Understanding these differences helps students align their interests with future-ready careers, whether through B.Tech. Chemical Engineering or B.Tech. Mechanical Engineering. Gear up and explore B.Tech. programs at Shiv Nadar University that encourage you to lead, innovate, and rise. Apply now!

FAQs

Can chemical and mechanical engineers work together?

Yes. In oil refineries, chemical plants, and pharma industries, both work side by side, from design to execution.

Which branch has more scope in the future, chemical engineering vs mechanical engineering?

Both fields have excellent scope. It depends on how one upgrades skills. Chemical engineers are key in the green tech and energy sectors. Mechanical engineers are central to automation and manufacturing.

Which branch is harder between chemical engineering and mechanical engineering?

Each comes with its own challenges. Chemical engineering can be math-heavy in kinetics and thermodynamics. Mechanical needs strong visualization and design accuracy.