Department of Chemical Engineering

Established in 2013, the Department of Chemical Engineering is a vibrant and interdisciplinary hub dedicated to research, innovative pedagogies, and real-world impact. The department integrates core engineering principles with chemistry, physics, mathematics, and biology to solve critical challenges in energy, environmental sustainability, healthcare, and advanced materials. The department provides high-quality education and prepares students for roles in various fields. Our comprehensive program offers students a deep and integrated understanding of core chemical engineering domains: fluid mechanics, chemical reaction engineering, thermodynamics, separation processes, heat and mass transfer, process control, and process design and safety. Beyond the fundamentals, the curriculum also highlights the evolving intersections of these areas with cutting-edge fields such as artificial intelligence (AI), nanotechnology, and sustainable engineering, empowering students to address real-world challenges with technical expertise and forward-thinking innovation. Whether one is aspiring to pursue research, drive industrial innovation, or shape sustainable practices, the Department of Chemical Engineering offers the knowledge, mentorship, and opportunities to make it happen.

Academic Programs

The department offers the following programs: Bachelor of Technology (B. Tech) in Chemical Engineering, with the option of a minor in any other stream, and Ph.D. in Chemical Engineering. Spanning eight semesters, the curriculum requires a minimum of 163 credits encompassing a broad spectrum of subjects, including basic and engineering sciences, core chemical engineering courses, and a diverse range of electives.

To connect the core areas of Chemical Engineering to industrially relevant themes, the department offers two specialisations at the undergraduate level:

The department has well-equipped laboratories for teaching and training undergraduate students. Our labs include:

- Unit Operations

- Mass Transfer

- Chemical Reaction Engineering

- Process Control Lab

- Computational facility

- Aspen Plus

- Ansys

- COMSOL Multiphysics

- MATLAB

- Dassault Systemes

The department has an active technical society (H2O) and an Indian Institute of Chemical Engineers (IIChE) student chapter. These platforms cultivate technical and managerial skills through regular events.

Research

The Department of Chemical Engineering has 10 experienced faculty members and one senior research scientist engaged in research across a broad range of areas and maintains active collaborations with both academic institutions and industries.

The department houses advanced research laboratories such as : Research Labs of Department of Chemical Engineering

- Biomass Conversion Lab (Professor Sanjeev Yadav)

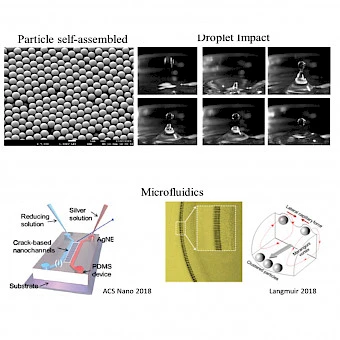

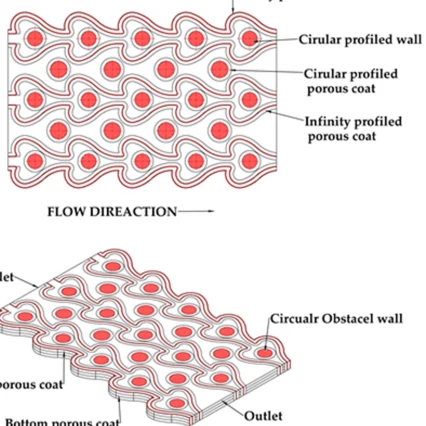

- Microfluidics Lab (Dr. V. M. Rajesh)

- Sustainability and Polymer Lab (Dr. Yamini Sudha Sistla)

- Energy and Environmental Sustainability Lab (Dr. Priyanka Katiyar)

- Intencity Lab (Dr. Dhiraj Kumar Garg)

- Soft Matter Lab (Dr. Ashish Kumar Thokchom)

- Polymer Materials Research Lab (Dr. Sanjay Krishna)

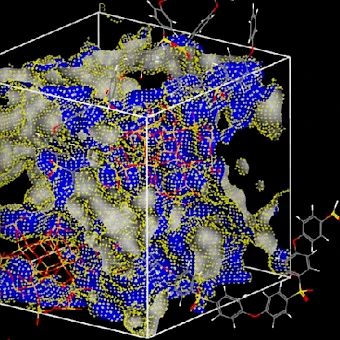

- Computational and Theoretical Soft Matter Lab (Dr. Swaminath Bharadwaj Gourishankar)

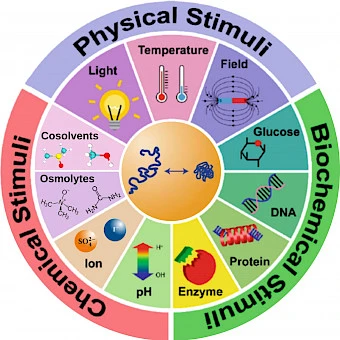

The research avenues in the department are organised into four broad themes aimed at bridging fundamental ideas with practical applications:

- Energy, Environmental and Sustainability

- Microfluidics

- Modelling and Simulation

- Polymers and Advanced Materials

Key research facilities include Fourier Transmission Infrared Spectrometer, Thermogravimetric

Analyser, UV-vis Spectrophotometer, Gas Chromatography-Mass spectrometer, Optical Microscope, Spin Coater, Rotary Evaporator, Supercritical Fluid Extractor, Multiphotometer, Membrane Casting Machine, Membrane Separation Unit and a mini GPU cluster.

Curriculum 2025 Onwards

Explore Programs under the Department of Chemical Engineering

Faculty at Department of Chemical Engineering

Swaminath Bharadwaj Gourishankar

Assistant Professor

School of Engineering

Department of Chemical Engineering

Explore Recent Research

Sustainable Maleic Anhydride

This project focuses on developing parallel milli-reactor systems for the selective oxidation of n-butane to maleic anhydride. The core of the work involves reactor design and flow optimization...

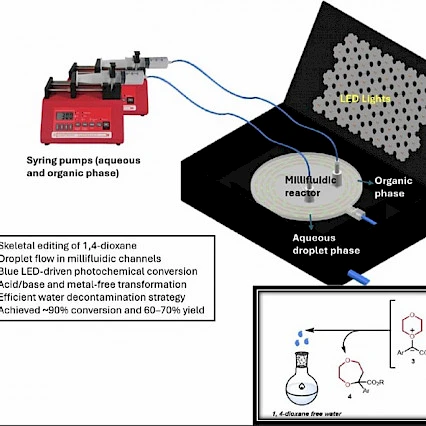

Visible-Light Water Purification

This project targets the elimination of 1,4-dioxane, a water pollutant that resists conventional remediation due to its high solubility and chemical stability. The work introduces a continuous-flow...

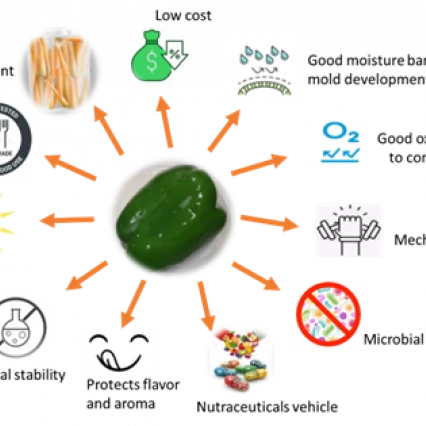

Biodegradable Packaging Films

This project aims to develop edible coatings and biodegradable packaging films to improve the shelf life of fresh produce and processed foods. The ultimate aim is to reduce the use of single use...

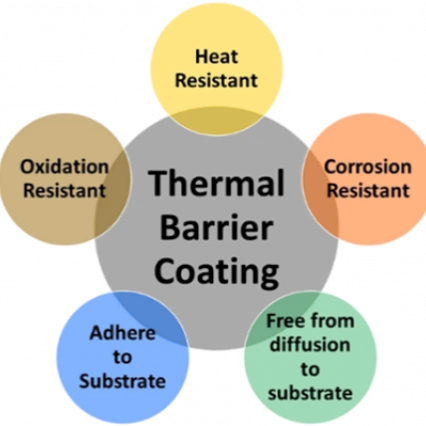

Thermal Barrier Coatings

The project aims to design and develop optimum high entropy oxide-based ceramics exhibiting low thermal conductivity and mechanical stability at high temperatures so that they can be used as...